Before I get started on today's post, I wanted to share something from the PHMC - today, January 15th, is Museum Selfie Day! Do you have a picture of yourself visiting one of Pennsylvania's museums or historic sites? Share it on social media and use the hashtag #MuseumSelfie so they see it! (Somewhat ironically, I do not have any such selfies.)

Growing up in Catasauqua, two things in particular stuck with me in terms of my education. One, I became an excellent speller, mostly in self-defense. Two, the town has a peculiar place in Pennsylvania's history. I mean, it's literally the birthplace of the American Industrial Revolution, thanks in part to founding father David Thomas. It has, as of this writing, six different PHMC markers, which is kind of impressive when you remember that the town is roughly a mile square in size. Most of the subjects of those markers are fairly well known to me, and indeed I've already covered Father Thomas and George Dery. However, today's subject was one that had me scratching my head a little bit, because what's so special about horseshoes?

Growing up in Catasauqua, two things in particular stuck with me in terms of my education. One, I became an excellent speller, mostly in self-defense. Two, the town has a peculiar place in Pennsylvania's history. I mean, it's literally the birthplace of the American Industrial Revolution, thanks in part to founding father David Thomas. It has, as of this writing, six different PHMC markers, which is kind of impressive when you remember that the town is roughly a mile square in size. Most of the subjects of those markers are fairly well known to me, and indeed I've already covered Father Thomas and George Dery. However, today's subject was one that had me scratching my head a little bit, because what's so special about horseshoes?

|

| The marker is located outside the Phoenix Forging Co. plant, 800 Front Street. |

More than I would have expected, that's for sure. David Thomas had a small hand in this project too - the plant was founded by a man named Oliver Williams, a native of Catasauqua who had moved away, but returned in 1880 at the suggestion of his pal David. David Thomas, as readers of that post might remember, was an iron master, and Williams, who took up the post of president of the Catasauqua Manufacturing Company, operated iron mills. He wanted to make something (I feel like that sometimes too) and, after spending a couple years getting used to the Lehigh Valley and a feel for what might be needed, he settled on horseshoes. Rather, on "Bryden Horse Shoes."

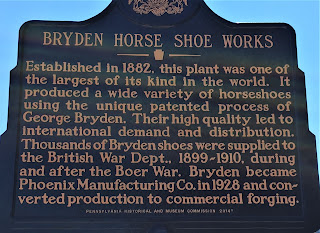

Obviously, his name was not Bryden, but that was the name he gave to the plant, which opened in 1882. The reason for the naming is because Williams manufactured his horseshoes using the method devised by a man named George Bryden in Hartford, Connecticut, from whom Williams got the patent rights. The usual way of making horseshoes at the time involved the shoes being rolled, with the heel and toe caulking welded into place by a blacksmith. Bryden's process, by comparison, involved the shoes being made start to finish with a heavy hammer. Despite my best efforts, I actually can't seem to find anything about George Bryden himself; every search for him or his horseshoe manufacturing method leads me back to information about the Catasauqua plant. He seems to have sold the patent to Oliver Williams and then faded into obscurity.

The original Bryden plant was a one-story brick building on the northwest corner of Railroad and Strawberry Streets, next to another company Williams owned. Horseshoes were, of course, something sorely needed in the 1880s, and the Bryden plant was initially producing as much as three tons of the shoes per day. By 1888, demand was threatening to exceed supply, which meant that it was necessary to create a bigger plant, and the property which is today located at 800 Front Street was purchased; once North Catasauqua was formed out of part of Allen Township in Northampton County, the Bryden plant basically straddled the border (as it still does today). Williams brought in a new superintendent for his new facility, Jacob Roberts, who was part owner of the Phoenix Horse Shoe Company in Poughkeepsie, New York - remember that later. In 1889, Roberts began turning the new property into what would become one of the world's largest manufacturers of horseshoes. He gave the new building a complete rolling mill, as well as bending and pressing irons designed to make nothing except shoes for horses and mules. The company became particularly famous for its "Neverslip" brand of winter horseshoes; they even made horseshoes specifically for kids to throw, advertising that you could get more 'ringers' with a Bryden horseshoe.

Another addition to the Bryden 'family' about this time was George Holton, a young Englishman, who had been working as an inspector of tunnel segments when the Davies and Thomas Co. was building them to create the Hoboken Tunnel. Williams became acquainted with the man, was impressed by his knowledge of the iron industry, and hired him as a traveling salesman. Between the high quality of the Bryden products and Holton's iron expertise, the horseshoes were in demand not just all over the United States but internationally.

Edit 1/17/2020: I have fixed some details regarding George Holton's original employment and just how North Catasauqua was formed. Thank you to Deb from the Historic Catasauqua Preservation Association for the corrections!

Edit 1/17/2020: I have fixed some details regarding George Holton's original employment and just how North Catasauqua was formed. Thank you to Deb from the Historic Catasauqua Preservation Association for the corrections!

(Be sure to click on the links down in the Sources section - there are photographs of the old plant, as well as of some of the tools and paperwork associated with the manufacture and sale of Bryden horseshoes.)

It was because of Holton that Bryden was able to become as important as it did; his biggest sales success was to the British government, who purchased large quantities of horseshoes from 1899 to 1910 for a little event known as the Boer War. Because of this, the facility was able to go to full employment and became one of the Lehigh Valley's largest industrial employers. This might also have been part of the reason why Holton was brought into not only the Bryden 'family,' but also the Williams family - he married Oliver Williams's youngest daughter Jessica.

Jessica and her sisters, Grace and Winifred, jointly inherited ownership of the Bryden plant when their father died in 1904. George Holton took over as president of the plant until his own death just nine years later, at which point Jessica herself assumed the position. Under the Holtons' leadership, Bryden continued to grow; by 1914, the plant property was seven acres in size, with around 300 employees producing between 40 and 50 tons of horseshoes each day. Of course, they started running into a new problem around this time, because "horseless carriages" - cars - became increasingly more popular and the demand for horseshoes began to shrink.

Remember Jacob Roberts, the superintendent of Bryden back when the Front Street property was first built? I mentioned that he was part owner of the Phoenix Horse Shoe Company up in Poughkeepsie. They were having the same problem, with the reduced demand, and it was eventually decided that they would purchase the Bryden plant as part of a diversification plan. It was in 1928 that the Phoenix Manufacturing Company, as it was now known, acquired Bryden; the new owners found that the Catasauqua location was very suitable for modernizing, and by 1939, it had been changed from horseshoe manufacturing to producing commercial forging and flanges. Phoenix continued to buy and liquidate other horseshoe facilities, but kept the old Bryden plant running.

|

| Phoenix Forging as it appears today |

And it's still running. Having gone through several ownership changes and some slight name adjustments, the Phoenix Forge Group continues operations on Front Street today. It's been upgraded and modernized as needed. Today it's a 120,000 square foot facility, one story high, made of steel and concrete and still situated on the Bryden site.

Bryden didn't get its PHMC marker until 2014, by which time I had myself moved out of the borough. That's probably why the name didn't mean anything to me until I started this blog; I certainly don't remember it coming up at any point in my high school history classes. I have to wonder if most people in Catasauqua even knew about it before the marker was posted. Sometimes I think the most important thing I'm going to do with this blog is show people what's in their own backyard - myself included. I grew up hearing the names Thomas and Dery, but I have no memory of anyone mentioning Oliver Williams or Bryden horseshoes. Good thing we have these markers to tell us more about what we've missed.

Sources and Further Reading:

Historic Catasauqua Preservation Association. Dedication announcement for PHMC marker, 2014; author unknown.

Shipley, Chris. "Catasauqua marks site of old Bryden Horse Shoe Works." The Morning Call, July 26, 2014.

The Hopkins Thomas Project. "The Bryden Horseshoe Company." Author unspecified, March 2010.

Werner, Beverly. "The Horseshoe." Posted on Another Day in Catasauqua, August 14, 2011.

Bryden Horse Shoe Works at the Historical Marker Database.

Except where indicated, all writing and photography on this blog is the intellectual property of Laura Klotz. This blog is written with permission of the Pennsylvania Historical and Museum Commission. I am not employed by the PHMC. All rights reserved.

Thanks so much for the great blog!!!

ReplyDeleteA couple of corrections: when N Catty was formed, it broke off from Allen Twsp in Northampton.

David Thomas was not involved in the Davies and Thomas Co that made tunnel rings - that was another Thomas family, that of Hopkin Thomas.

Feel free to visit HCPA - and the borough's - history pages at www.history.catasauqua.org

Deb, thank you so much for the kind words and also for the corrections! I have edited the post accordingly and credited you for the help. I appreciate it deeply.

DeleteThank you for the wonderful story about "The Horseshoe". I grew up 3 blocks east, at Third and Arch. Woke up and sometimes went to sleep with the sounds of the drop-forge beating a drum tattoo as the iron became U-joints, hammer heads, and of course horse shoes. Before the building was completely screened from public view, one could see the work being done. In the summer especially large sliding doors were opened and we could watch the forge hammers pound the metal. Sparks would fly and the yellow hot metal gradually cooled to red then grey. The men held the bars using long tongs and, if necessary turned the mass between forging until a recognizable shape would emerge. Thanks for the memory.

ReplyDeleteThank you so much! I'm glad you enjoyed the post and that I could bring back that memory for you!

DeleteGeorge Bryden was from Hartford, CT. Williams built a test plant in CT to take the patent info from concept to a commercially-feasible process. He then moved all the equipment to the Union Foundry site here at the corner of Railroad and Strawberry. When it outgrew the site, he relocated the plant to its present location.

ReplyDeleteHCPA will be giving a presentation on the Bryden Horseshoe/Phoenix Forge at the Whitehall Historical Preservation Society Helfrich Springs Grist Mill on Wednesday, April 29th at 7pm.

ReplyDeleteThank you for this information, Deb! I will be sure to share it with my readers!

Delete